Дом > Продукты > рециркуляционный чиллер > Запечатанный чиллер > -80℃ Герметичный рециркуляционный охладитель

Интеллект создает будущее

Ключевые слова: роторный испаритель, циркуляционный насос для отопления и охлаждения, рециркуляционный чиллер

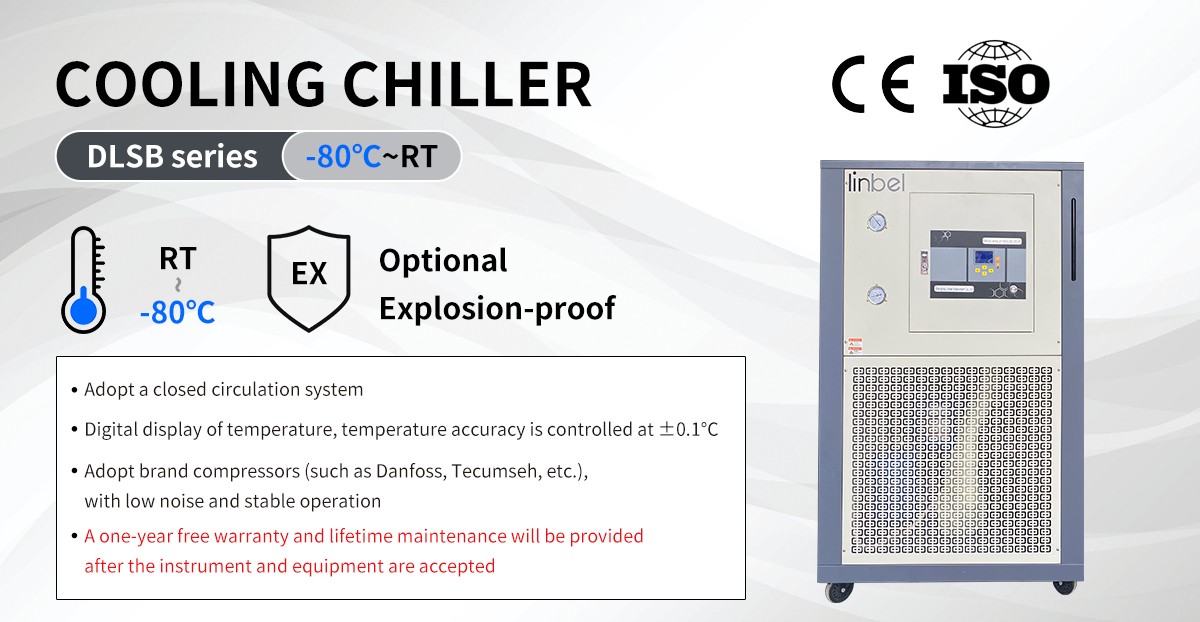

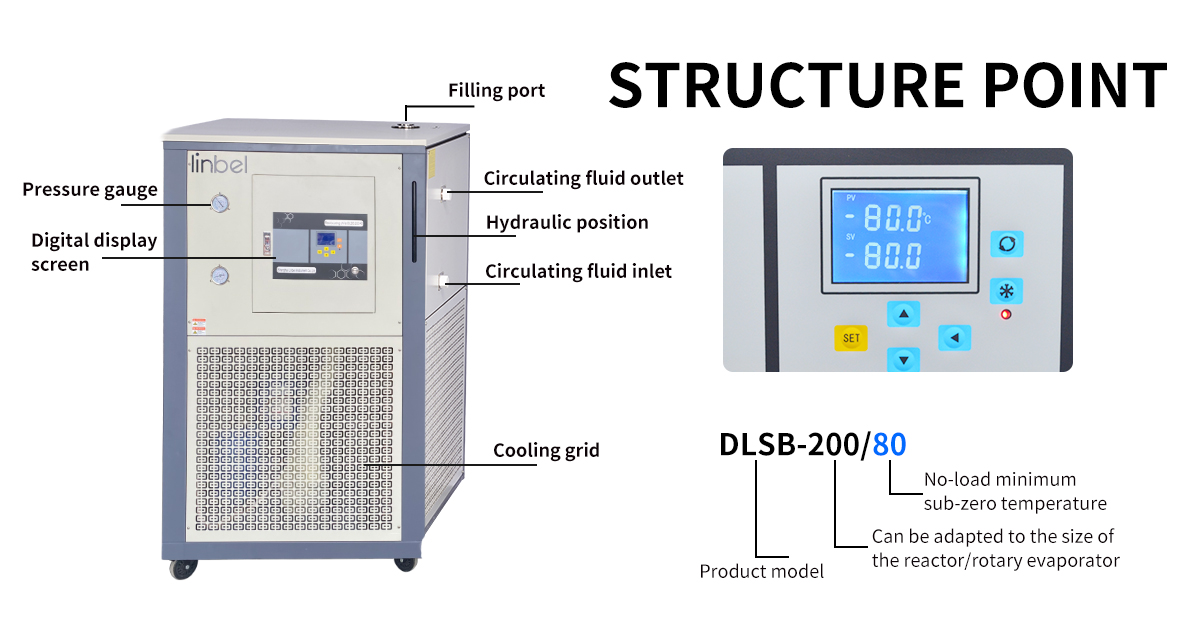

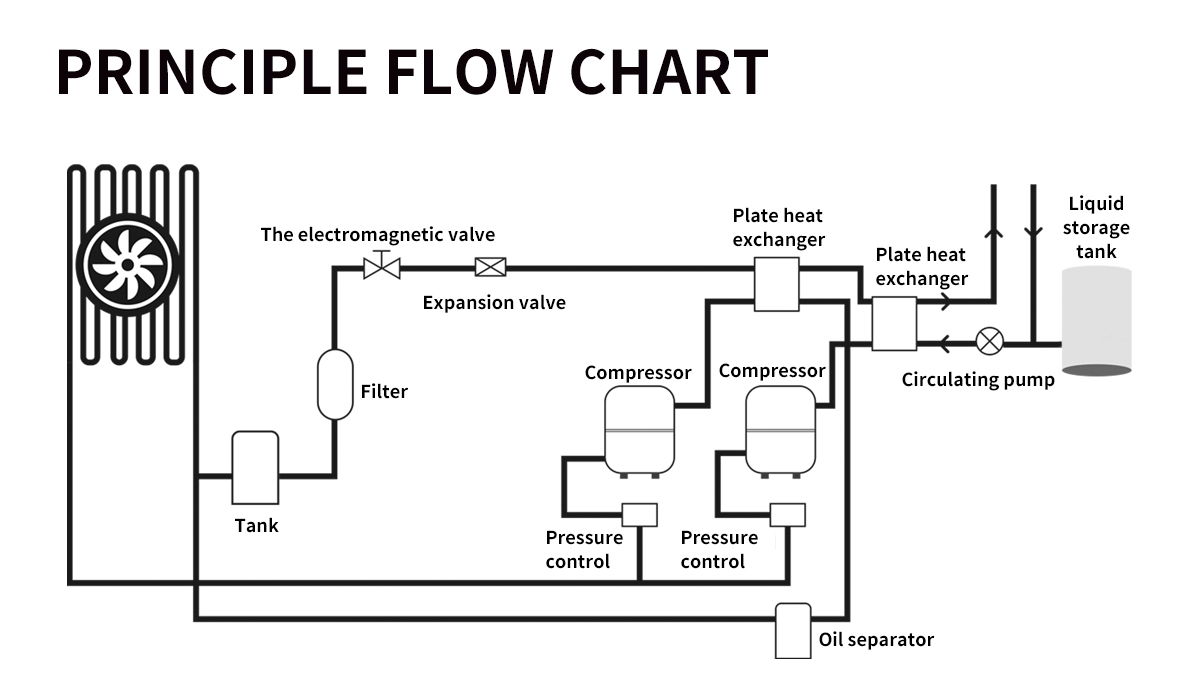

Low temperature refrigeration circulator, the minimum temperature can reach - 80 ℃. The product uses the mixture of glycol and water for cycle refrigeration, saving water resources; Subcooling technology is adopted to ensure the temperature stability at low temperature; Fully enclosed design ensures the purity of cold and heat conducting medium, prevents ice crystal and improves the service life of heat conducting fluid.

Model | DLSB-5/80 | DLSB-10/80 | DLSB-20/80 | DLSB-40/80 | DLSB-50/80 | DLSB-100/80 | DLSB-200/80 | DLSB-300/80 | ||

Technical data | Temperature range | -80~RT;±1℃ | ||||||||

Ambient temperature(℃) | ≤30℃ | |||||||||

Ambient humidity | 60% | |||||||||

Voltage(V) | 110/220 | 220 | 220 1P/3P 380 3P 460 3P | 220/380/460 | ||||||

Phase(P) | 1 | 6 | 7 | 10 | 13.3 | |||||

Frequency(Hz) | 50/60 universal | 50 or 60 non-universal | 50/60 universal | 50 or 60 non-universal | 50/60 universal | |||||

Power(Kw) | 1.6 | 3.3 | 5 | 5.6 | 10 | 10 | 16 | 20 | ||

Cooling capacity(w) | 25℃ | 2044 | 4500 | 6750 | 7665 | 13500 | 18000 | N/A | ||

5℃ | N/A | 29610 | 32479 | |||||||

0℃ | 1850 | 4100 | 6100 | 7300 | 12000 | 15750 | 24950 | 27232 | ||

-10℃ | N/A | |||||||||

-30℃ | ||||||||||

-40℃ | 1200 | 2600 | 4500 | 5800 | 8500 | 10565 | 11000 | 13549 | ||

-60℃ | 900 | N/A | 7623 | 7663 | ||||||

-80℃ | 170 | 292 | 550 | 900 | 1100 | 1500 | 1701 | 2678 | ||

Temperature sensor | PT100 | |||||||||

Protection | Overvoltage, time delay, overcurrent, overheating, leakage, protector | |||||||||

Compressor | Type | Closed | ||||||||

Brand | Danfoss | Tecumseh | Danfoss | |||||||

Power(Kw) | 1.5 | 3 | 4.5 | 5.25 | 9 | 9 | 15 | 19.5 | ||

Current(A) | 7 | 13 | 20 | 23 | 30 | 30 | 30 | 38 | ||

Horsepower | 1 | 1.5 | 3 | 3.5 | 6 | 6 | 10 | 13 | ||

Quantity | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | ||

Refrigerant | R404A、R23 | |||||||||

Condenser | Type | Air cooling | ||||||||

Fan type | External rotor axial flow fan | |||||||||

Quantity | 1 | 2 | ||||||||

Evaporator | Type | Plate heat exchanger | ||||||||

Tank volume(L) | 5 | 7 | 10 | 10 | 17 | 35 | 100 | 100 | ||

Flow(L/min) | 15 | 25 | 35 | 35 | 35 | 35 | 97 | 97 | ||

External circulation adapter size(DN) | 15 | 15 | 20 | 20 | 20 | 20 | 20 | 20 | ||

Circulating pump | Type | Magnetic pump | Shield pump | Magnetic pump | ||||||

Brand | Puneet | Shanghai Jingyi | Puneet | |||||||

Power(w) | 15 | 100 | 280 | 280 | 280 | 280 | 550 | 550 | ||

Current(A) | 0.5 | 0.5 | 1.2 | 1.2 | 1.2 | 1.2 | 2 | 2 | ||

Rated head(m) | 3 | 8 | 8 | 11 | 11 | 11 | 15 | 15 | ||

Rated flow(L/min) | 15 | 25 | 25 | 35 | 35 | 35 | 180 | 180 | ||

Appearance dimension | Running weight(Kg) | 95 | 210 | 250 | 255 | 330 | 350 | 570 | 590 | |

Chiller size | Length(mm) | 600 | 770 | 810 | 810 | 970 | 970 | 1400 | 1400 | |

Width(mm) | 480 | 670 | 710 | 710 | 800 | 800 | 970 | 970 | ||

Height(mm) | 770 | 1180 | 1240 | 1240 | 1245 | 1345 | 1580 | 1780 | ||

*PLC

| Control system | Siemens S7-200 smart PLC | ||||||||

Programming | 5 programs can be written, each with up to 40 steps | |||||||||

Control model | Material temperature and equipment outlet temperature can be switched automatically | |||||||||

Protocol | Modbus RTU protocol RS485 interface (optional RS232 Ethernet) | |||||||||

Control panel | 7-inch Siemens color touch screen (optional 10 inch) | |||||||||

Data export | Support USB flash disk data export, and export temperature data in TXT format | |||||||||

Packing list | 2 sets of adapter valves, one roll of raw meal | |||||||||

2 stainless steel insulated hoses | ||||||||||

Operation instructions | ||||||||||

All data are measured in the factory, and users will have errors in the process of use | ||||||||||

*PLC for optional PLC part data, it is not applicable if there is no PLC | ||||||||||