Интеллект создает будущее

Ключевые слова: роторный испаритель, циркуляционный насос для отопления и охлаждения, рециркуляционный чиллер

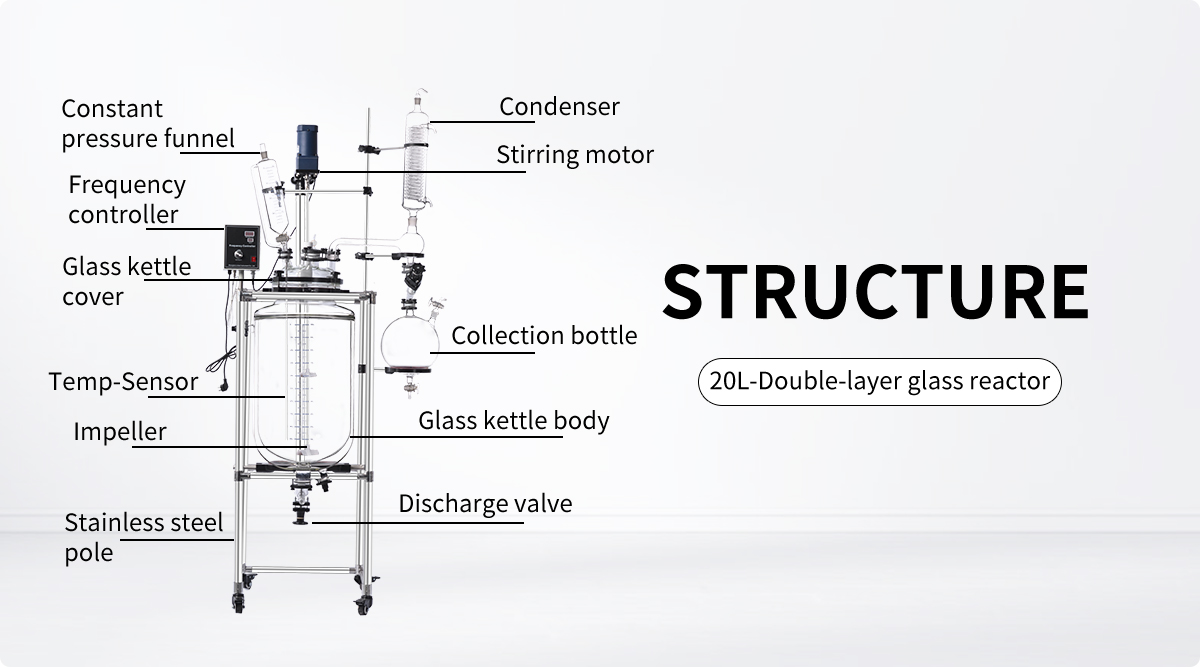

The double jacketed glass reactor is made of double glass with high borosilicate as raw material, with high permeability and corrosion resistance. The reaction medium is put into the inner layer for stirring reaction, and different cold and heat sources can be connected to the interlayer for circulating heating or cooling reaction.

Model | GR-100L | |

Volume(L) | 100 | |

Jacket volume(L) | 30 | |

Condensation area(m²) | 1.1 | |

Feeding tank volume(L) | 2L | |

Recovery tank volume(L) | 20 | |

Kettle cover diameter | Impeller diameter | 60# flangetype |

Temperature sensor diameter | 40# flangetype | |

Condenser connection | 50# spherical grinding | |

Liquid feed inlet | 34# standard grinding×1 | |

Feeding tank interface | 40# standard grinding | |

Solid feed inlet | 80# flangetype | |

Glass assembly | High borosilicate glass 3.3 | |

Main frame | SUS304 | |

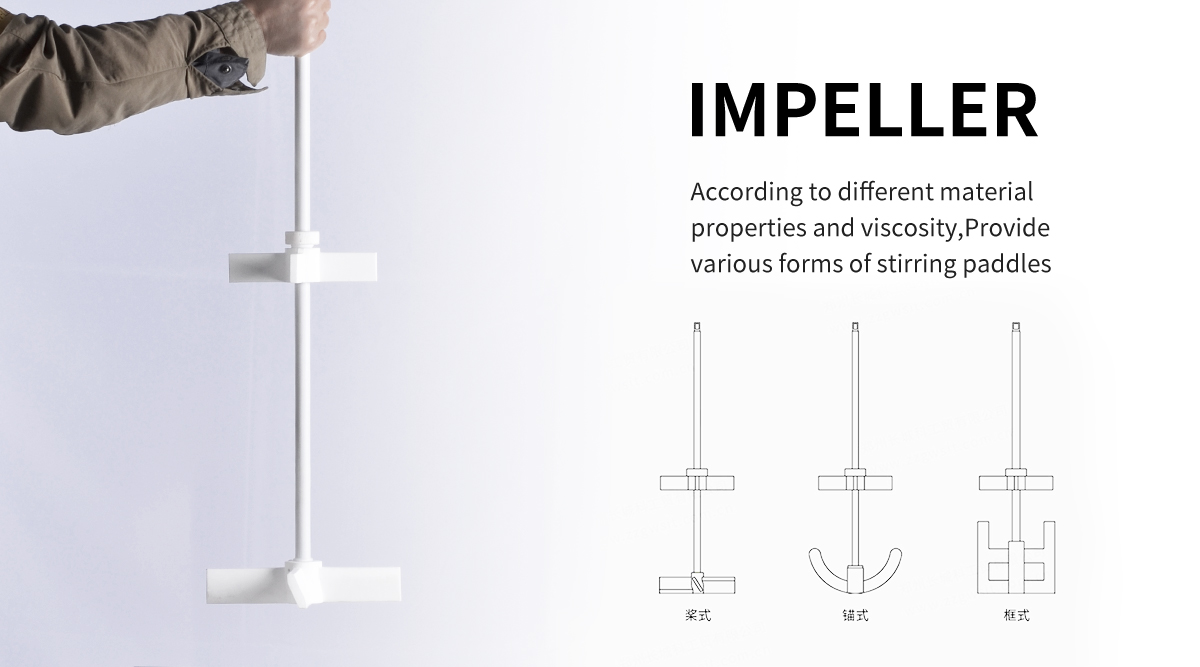

Stirring paddle | Paddle agitator, internal stainless steel, external polytetrafluoroethylene (PTFE), titanium | |

Motor | For viscous materials, high-power motors can be used | |

Move method | Lockable casters | |

Working temperature(℃) | -120℃~300℃ | |

Maximum temperature difference(℃) | ≤60 | |

Pressure in kettle(MPa) | -0.1~0.1 | |

Jacket pressure resistance(MPa) | ≤0.1 | |

Pressure rise rate of vacuum system | ≤2kPa/h | |

Mixing motor power(W) | Common 200W/ explosion proof 370W | |

Speed regulation mode | Frequency control | |

Speed adjustment range(rpm) | 0~600 | |

Temperature sensor | PT100 | |

Temperature display accuracy(℃) | ±0.1 | |

Temperature range | Water: RT~90℃ | |

Oil: RT~300℃ | ||

Interface size of stainless steel insulation hose | ½in external screw thread | |

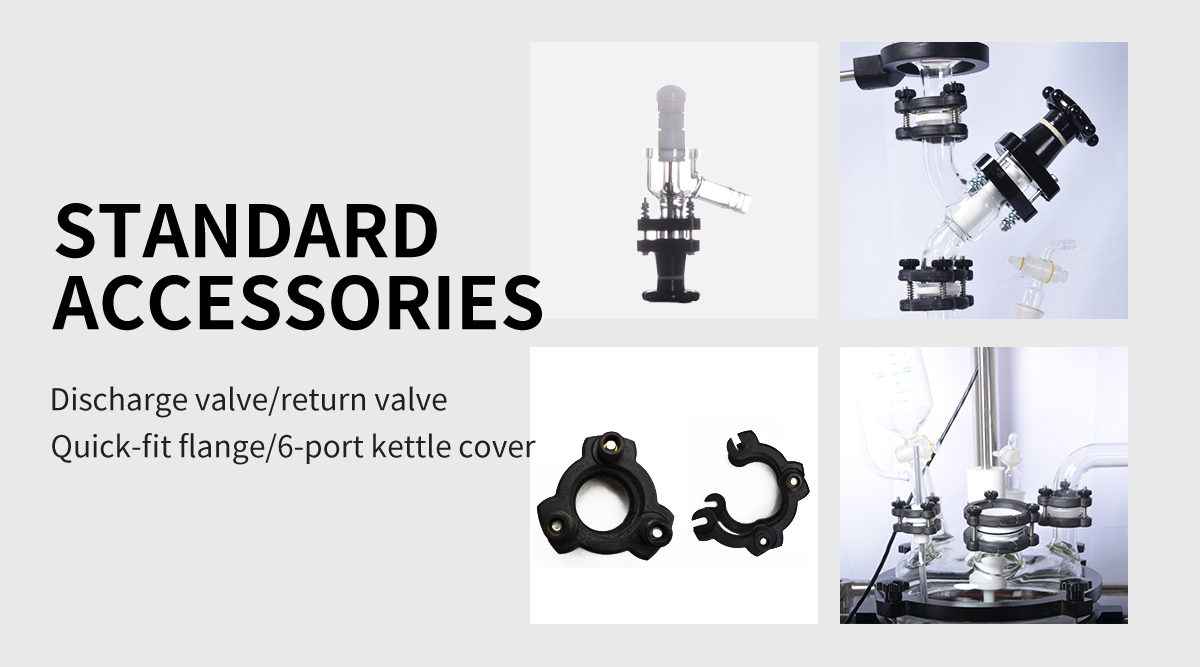

Seal material | PTFE | |

Installation height of discharge valve(mm) | 450 | |

Power | 220V/110V,50/60Hz | |

Environment temperature(℃) | 5~35 | |

Relative humidity(%) | ≤ 65 | |

Size(mm) | 800W×710D×2600H | |

Weight(kg) | 128 | |